Embracing Innovation:

PIE Solutions Integrates SLS Print Technology

-

SLS Integration

PIE Solutions First SLS Print

Welcome to PIE Solutions! -

The Printer!

Write your caption herePrinter Informational Video

Printing Parts

Using FUSE 1+30W

Button

Cleaning Parts

Using Fuse Sift

Button

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton-

Everything gets extra attention

Button

Getting Ready for Assembly

Button

The Blueprints

Button-

Slide title

Contact Us Today

Pushing Boundaries:

In a strategic move to stay ahead of the technological curve, we are excited to announce the expansion of our capabilities through the utilization of a cutting-edge Selective Laser Sintering (SLS) printing. SLS technology supports the production of complex geometries that were once challenging or impossible to recreate with traditional manufacturing methods. By bringing SLS capabilities in-house, we expedites design timeline and help our clients ensure a competitive edge. As SLS printing continues to redefine the possibilities of additive manufacturing, we are excited to grow with this technology.

PIE Solutions and SLS Design Advantage:

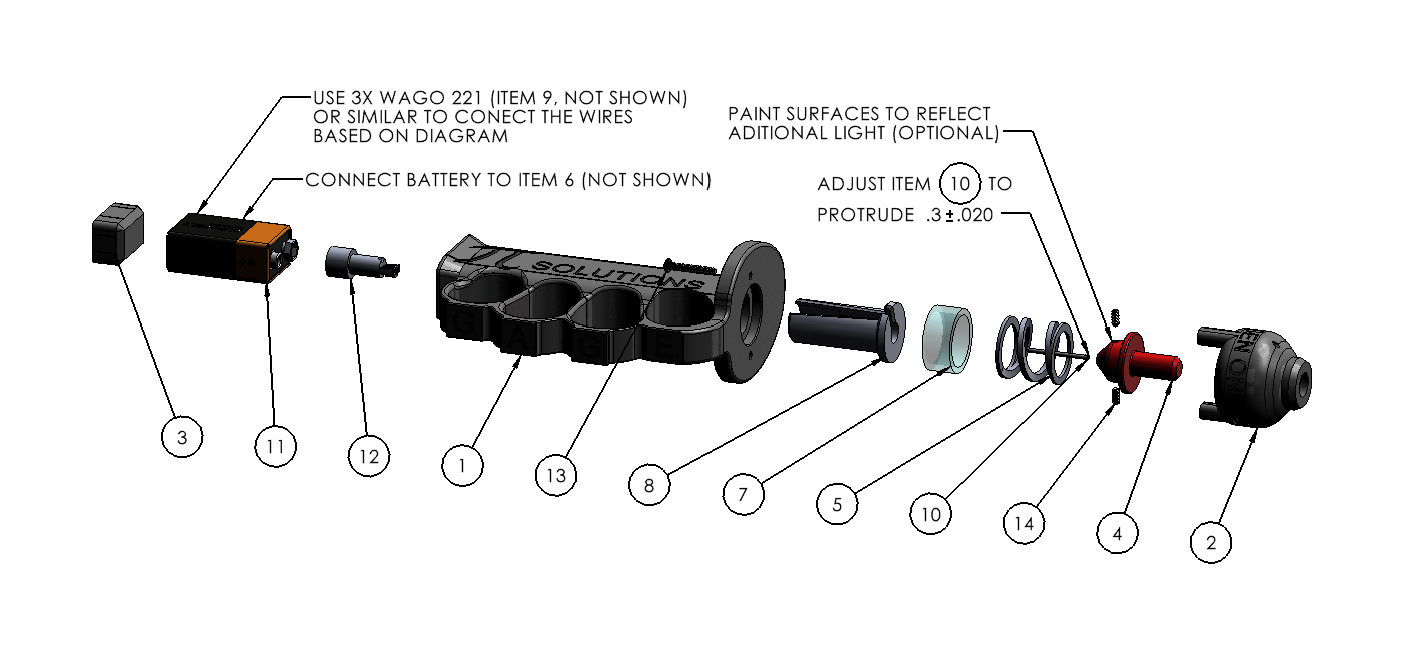

SLS is a revolutionary process that utilizes a high-powered laser to selectively fuse powdered materials layer by layer to create complex production quality parts. One unique aspects of SLS printing is the ability to print assembled designs. SLS technology does this by taking advantage of powdered material support to print parts in extreme proximity from one another. In many builds this can save assembly time and eliminate assembly errors. One of the ways we use this feature to our advantage is by printing multipart PCB tester setups in already assembled configuration. Another advantage of using SLS is the mechanical multi-directional reliability and part consistency that allows SLS to be used to create compliant mechanism parts. We capitalise on this unique feature by printing compliant mechanism parts that utilize part geometry to bend themselves in a complex way to serve a specific function. Below is a list of examples of how PIE Solutions has utilized SLS technology so far.

Pie Solutions Custom Designs Using SLS:

- Process development adjustable, locking spreader tool

- Tensile stress linkage system for Instron material testing

- Electronic gage with linear actuation

- Assembled Integrated buttons

- Assembled spring-loaded lockbox

- PIE Solutions research prototypes

- Different surface finish, texture, fabric, and external customization samples

- Airtight assembly

Contact

Make the best of your business. Contact us to schedule a consultation.

aostrer@piegroupdesign.com

We will get back to you as soon as possible.

Please try again later.